Steel Sheet Piles Types

1-Types - Hot Roolled Steel Sheet Piles

Hot-Rolled Steel Sheet Piles (Larssen Sheet Piling)

🔥 Manufacturing Process

Hot-rolled steel sheet piles are formed from molten steel billets through a gradual hot-forming process. This creates precise cross-sectional profiles and interlocks for seamless connections.

Key Advantages

🔒 Watertight Performance

Tighter interlocks (e.g., Corus, Hoesch Frodingham, ball-and-socket) ensure superior resistance to water penetration.

🏗️ High Structural Strength

Optimized profiles provide exceptional bending resistance and load-bearing capacity, ideal for deep foundations and lateral pressure from soil/water.

⚙️ Versatile Installation

Compatible with vibratory hammers, pile drivers, or rigs, adapting to soil types and pile dimensions (length/thickness).

2- Types - Cold Roolled Steel Sheet Piles

Cold rolled or cold formed U type sheet piles are most widely used in Asia,like in China, Philippines, Indonesia, Malaysia, Singapore, Vietnam etc.In Middle east, we have shipped our cold rolled profiles to almost every country: Iraq, Iran, Jordan, UAE, Saudi Arabia, Bahrain, Kuwait, Pakistan etc. In Australia,Africa,North and South America,we also have numerous clients and projects. Sheet pile can be supplied in single pile, double piles or even triple piles. Steel sheet pile contractors choose U profiles mainly because the interlocks are located on the neutral axis. In theory, our sheet pile factory can produce any size.

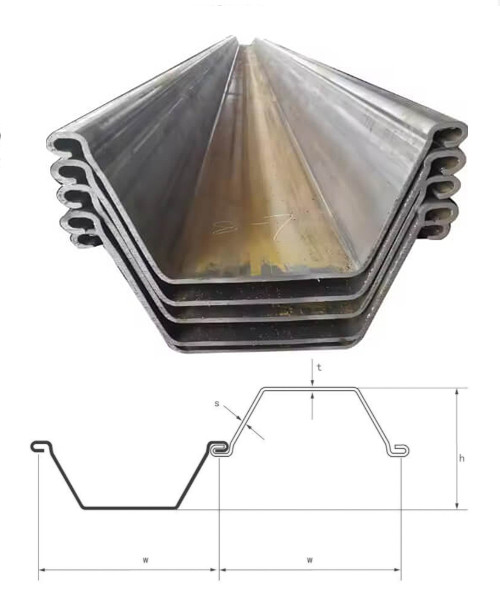

U shaped steel sheet pile

High strength, ideal for foundation pit support

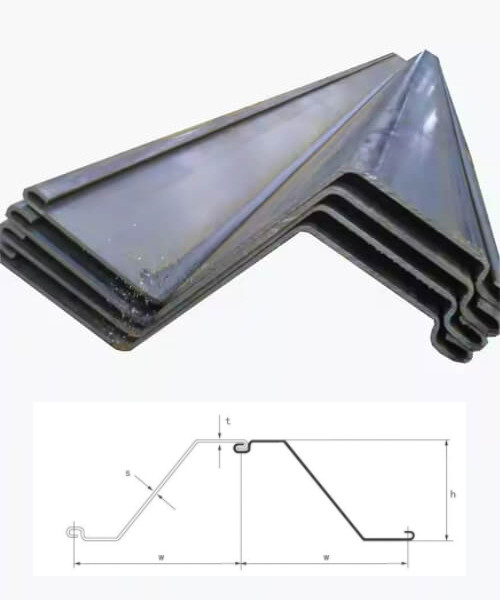

Z shaped steel sheet pile

Strong bending capacity, suitable for large span projects

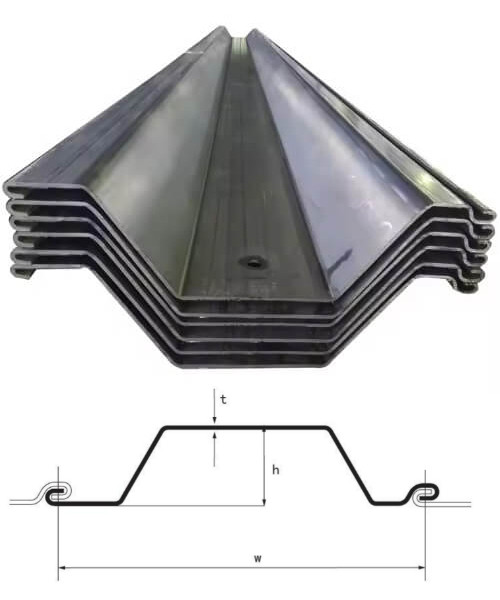

omega type sheet pile

Cost-effective, ideal for general construction

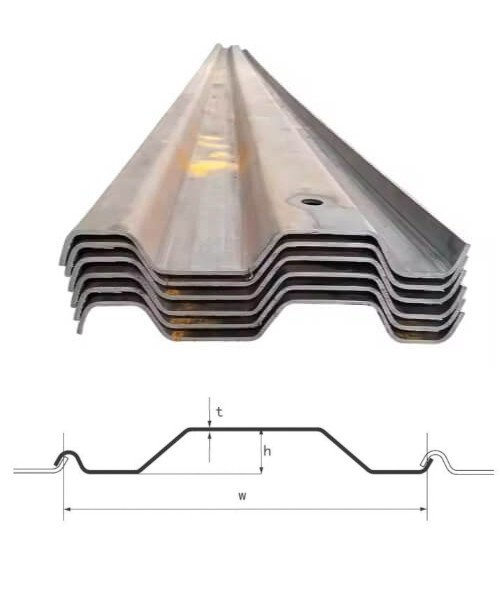

flat steel sheet pile

High strength, suitable for harsh environments

Key Benefits

✅ Lightweight & High Strength – 20% Cost Saving

✅ Global Certifications – EN 10249 & ASTM A328

✅ Multi-Scenario Use – Cofferdams/Tunnels/Bulkheads

3-Types - Pipe Piling

The tubular combined wall not only service as the retaining wall member, resisting horizontal loads, but also serve as bearing pile which resist vertical loads. The OZ sheet pile can be shorter than the tubular piles and only have the functions of earth retaining and load transfer. Nowadays the interlocks used in the combined piles have many choices on the market, C9 C14 are the most traditional sheet piling accessory.Further fabrications, like piling shoes, lifting ligs, weld beads, beveled ends, corner sections, paintings…etc we can all do in our workshops.SGS or BV Inspection report is normally supplied.

The tubular combined wall not only service as the retaining wall member, resisting horizontal loads, but also serve as bearing pile which resist vertical loads. The OZ sheet pile can be shorter than the tubular piles and only have the functions of earth retaining and load transfer. Nowadays the interlocks used in the combined piles have many choices on the market, C9 C14 are the most traditional sheet piling accessory.Further fabrications, like piling shoes, lifting ligs, weld beads, beveled ends, corner sections, paintings…etc we can all do in our workshops.SGS or BV Inspection report is normally supplied.

Tubular Pile Classifications

✅ SSAW steel pipe

✅ LSAW steel pipe

✅ Seamless pipe

✅ ERW pipe